One solution versatile

applications

SUSTAINABLE • EFFECTIVE • ECONOMICAL

Agromorph’s team of algal scientists, bioprocess engineers, chemical engineers, business professionals and industry veterans ensures sustainable, economical and scalable offerings for your industry. Our designs offer flexibility to utilize more than one waste stream to recover valuable resources making the business secure for the future.

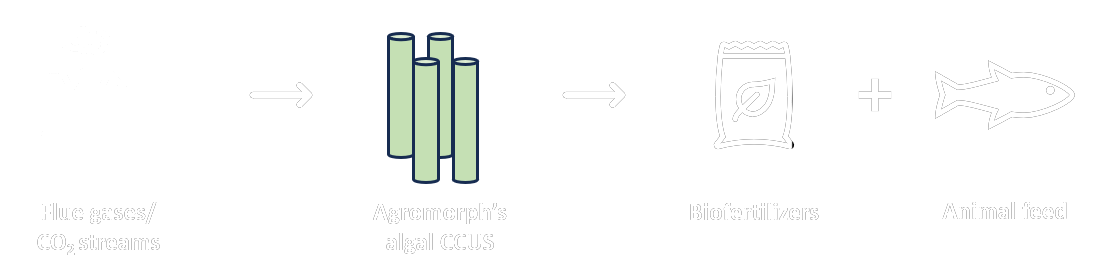

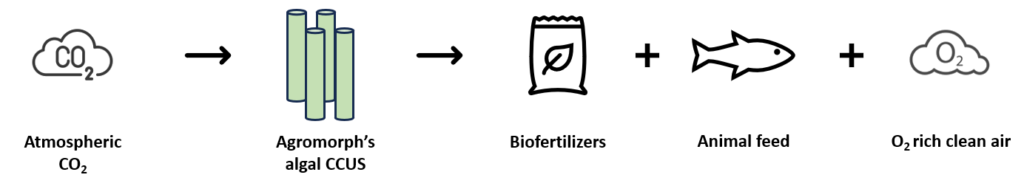

Carbondioxide to high value

enables new revenue streams

AgroMorph is working with major CO₂ emitters (like Steel, Oil & Gas) to convert flue gases into high value algae for protein, ingredients and biofertilizer purposes. While abatement techniques are a cost to these industries, AgroMorph’s financially and environmentally secure algal systems provide an exciting opportunity to generate revenue. E.g. 1000 ton of CO₂ can be converted into $1.8 Mn of revenue.

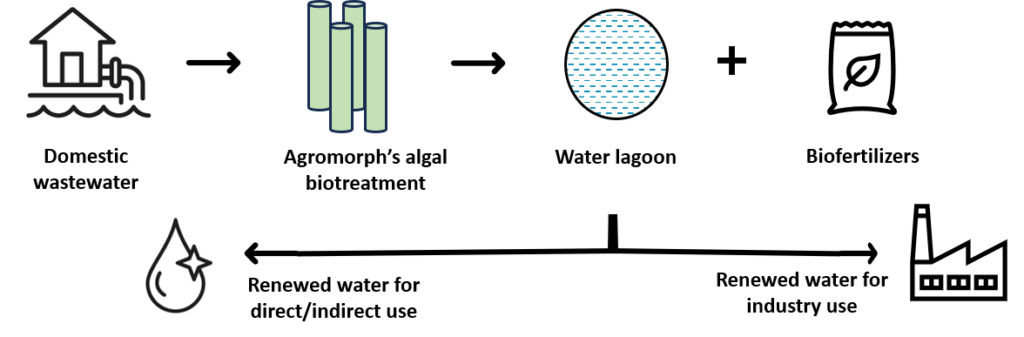

Waste Water to clean water for reuse

solves for global water scarcity and security

By bringing an engineered solution using algae to extract wastewater nutrients, we ensure that water is safe for reuse. AgroMorph has successfully completed technology demonstrations and is now implementing commercial scale projects for decentralized domestic wastewater treatment and reuse. Algae, our by-product in the process, is used as a biofertilizer. This offers significant socio-economic benefits with a positive environmental impact.

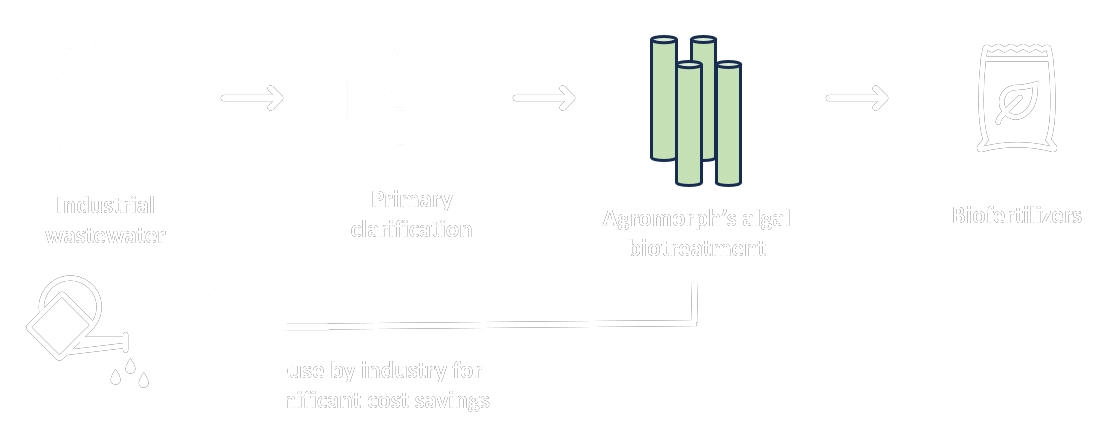

Industrial wastewater to clean water

added benefit of revenue from algae

Wastewater treatment in effluent streams is a cost to industries. We convert these streams to value using AgroMorph’s robust algae strains that are tested to consume high COD effluents. Our algae offer a unique opportunity to recover N, P, K & C from wastewater solving odor issues as well as high N in the final effluents. Algae, our byproduct, is further processed to recover the valuable nutrients.

Algal ingredients using photobioreactors

carbon sequestration advantages

Algae production in open raceway ponds has high footprints and is prone to contamination. AgroMorph’s modular designed photobioreactors (PBRs) enable footprint reduction by more than 70% and OpEx reduction by 70% with 5-fold higher yields when compared to raceways.